HDPE Pipe Fusion

Pipe fusion involves joining two pieces of High Density Polyethylene (HDPE) pipe together using 420 – 450 degree heat and hydraulic pressure. When the butt weld is cool, the joint is 20% stronger than the pipe.

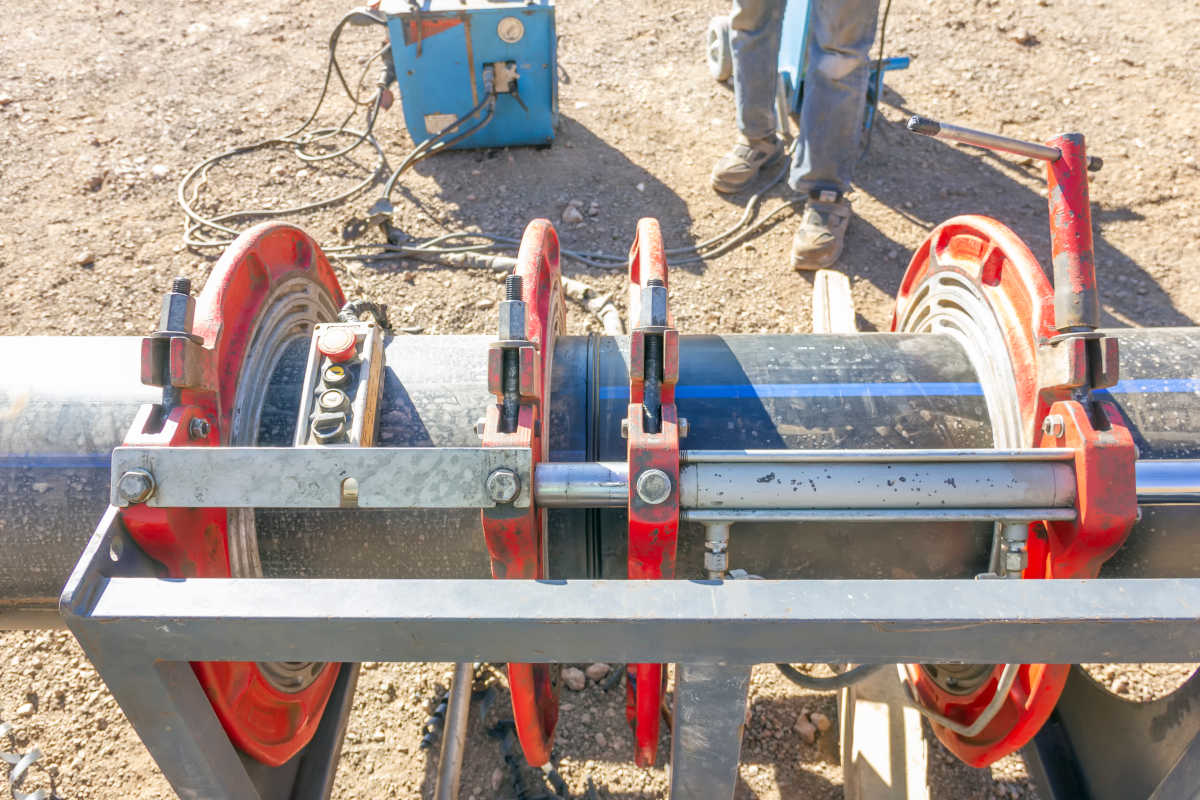

We use McElroy Fusion machines for our pipe fusing. We start off with the correct sized inserts for the pipe being fused. Next, we install two pieces of pipe in the machine and clamp in place. The ends of the pipe are faced off by rotor knife, the rotary knife is removed and a pre-heated, heater plate insert between pipes is left in until the pipe has melted properly on the ends. Then, the heater plate is removed and hydraulic pressure is used to bring the ends of the pipe together and hold under pressure until butt fusion has cooled to 100 degrees.

The main benefit of pipe fusion is that the HDPE is one continuous piece of pipe, so there is no potential for leaks or tree roots’ intrusion.

Contact us for more information or to request a free estimate on your project!